EcoPhi Basic Controller

You can also find our video tutorials here: https://www.youtube.com/@EcoPhiRenewables

1 Introduction

1.1 Description and function of the EcoPhi Basic Controller

The EcoPhi Basic Controller is a modern communication edge device that has been specially developed for the requirements of renewable energy systems. The device enables the monitoring and simple control of serial devices, sensors and actuators and provides a central platform for data processing.

The Basic Controller was developed by EcoPhi, a company specializing in innovative IoT solutions for renewable energy. EcoPhi focuses on providing efficient and robust technologies that enable customers to optimally operate and monitor their systems. The Basic Controller plays an important part in this offering, as it ensures reliable data collection and a stable connection to the EcoPhi Cloud.

The EcoPhi Basic Controller is a central component of modern energy systems that combines several essential functions. It was developed to collect data from connected external devices and sensors, process it locally and make it accessible via a cloud platform. The Basic Controller is mainly used to collect data, but can also to be used for simple control functions.

1.2 Safety instructions

The installation and operation of the EcoPhi Basic Controller requires compliance with basic safety regulations to ensure the safety of persons and equipment:

Installation by qualified personnel: The Basic Controller may only be installed and maintained by qualified specialist personnel in order to avoid risks such as electric shocks or malfunctions.

Switch off the power supply: Before installation or maintenance, ensure that the power supply to the device is disconnected.

Use the components supplied: Only use the parts recommended or supplied by EcoPhi to ensure functionality and safety.

Seal cable glands: Open cable glands must be properly sealed before commissioning to prevent the ingress of moisture or foreign bodies.

Notes on correct cabling and proper connections

- It is strongly recommended to use shielded cables.

- Ensure that there are no sources of interference near the cables, e.g. motor cables, power cables, high-power cables.

- The greater the distances, the greater the influence of possible sources of interference

- Connect cables properly and not via loose plug contacts or simple insulating tape.

- If necessary, remove the supplied terminals from sensors supplied by EcoPhi, as they are not intended for permanent use, but only to show that the wiring is correct.

- If necessary, use the heat-shrink tubing supplied to extend and connect the cables.

For serial devices: Avoid star connections; the maximum distance for star connections is 100 m. A 120 Ohm resistor at the end of the connections improves transmission.

For pulse sensors: Avoid magnetic interference fields in the vicinity of pulse sensors, e.g. door sensors or water meters.

1.3 Glossary for the EcoPhi Basic Controller

- 2FF (Mini SIM): A specific SIM card format that is used with the EcoPhi Basic Controller.

- 4-20mA mode: Standard for analog signal transmission, often used with industrial sensors. The current range (4 to 20 mA) represents the measured value of the sensor.

- AI (Analog Input): Analog inputs that can detect changing states of sensors, usually through a sensor signal of 0-10V or 4-20mA.

- AO (Analog Output): Analog outputs that send signals to external devices.

- APN (Access Point Name): Network name that is required for the mobile connection to send and receive data via the mobile network.

- CSV (Comma-Separated Values): A file format used in the Basic Controller to save or import configurations and settings.

- DI (Digital Input): Digital inputs that can recognize binary states (on/off) of sensors or switches.

- DO (Digital Output): Digital outputs that send signals (on/off) to external devices such as relays or contactors.

- Ethernet: Wired network interface used for a stable connection and data transmission.

- GND (Ground): Earthing point in the Basic Controller that is important for the safe connection with other devices.

- Modbus: A communication protocol used in the Basic Controller to communicate with devices such as inverters or sensors via RS485 or TCP/IP.

- RS232: A standard for serial communication used in the Basic Controller for certain devices.

- RS485: A serial communication protocol that is often used in industrial applications. The Basic Controller supports it for connection to sensors and other devices.

- SD card: A storage medium used in the Basic Controller for data backup and configuration updates.

- SNR (Signal-to-Noise Ratio): Ratio of signal strength to noise, which describes the quality of a radio connection.

- SSID (Service Set Identifier): Name of a WLAN network that is required for the WiFi connection of the Basic Controller.

- VCC (Voltage Common Collector): Supply voltage for sensors or other connected devices.

- WiFi: Wireless network interface of the Basic Controller, which is used to connect to the EcoPhi Cloud or local networks.

1.4 Technical data

1.4.1 Power consumption

Under maximum load, the Basic Controller can consume up to 30 watts. This maximum power consumption typically occurs during intensive use, for example when numerous devices are connected or when a high data transfer rate is required.

In normal operation, however, the average power consumption of the Basic Controller is around 3 to 4 watts. This value varies depending on the number and type of sensors connected, the frequency of data transmission and the communication interfaces used, such as WiFi or Ethernet. The use of the integrated touchscreen can also increase power consumption.

The low average power consumption of the Basic Controller also makes it suitable for applications in energy-efficient systems, where minimizing power consumption is of central importance.

The EcoPhi Basic Controller requires a reliable power supply for operation, which is provided via 230V AC as standard. The incoming AC voltage is converted into 24V DC via an integrated AC/DC converter, which supplies the Basic Controller and the connected devices with energy.

Maximum power consumption: The Basic Controller has a maximum power consumption of 1.25A under full load, depending on the number and type of sensors and outputs connected. In normal operation, consumption is significantly lower, meaning that the device works efficiently and economically.

Emergency power supply: The Basic Controller is equipped with an internal battery that keeps the data logger operational for up to 4-5 hours even in the event of a power failure. This backup power solution ensures that important data continues to be stored and that there is no interruption in communication with the platform as soon as the main power supply is restored.

Alternative power supply: It is also possible to use your own or an alternative power supply. However, this must be compatible with the connected devices and be able to supply a voltage between 11.5V and 30V DC. Stable operation of the Basic Controller is only guaranteed if these specifications are met. A minimum supply of 14 VDC is required for the configuration of the 0-10 V analog output.

1.4.2 Data consumption

The data consumption of the EcoPhi Basic Controller depends largely on the connected devices, the frequency of data transfers and the quality of the internet connection. While a stable connection reduces consumption, unstable connections can lead to higher data consumption due to repeated or repeated connection attempts.

In a typical system comprising a moderate number of sensors and devices, the average monthly data consumption is around 200 MB. However, this value can vary considerably. Systems with a higher number of sensors or more frequent transmission intervals require correspondingly more data volume. Conversely, consumption can be reduced for systems with fewer data points or longer transmission intervals.

The Basic Controller is therefore designed to keep data consumption efficient by only transmitting relevant data and minimizing unnecessary repetitions. This also makes it suitable for systems that rely on mobile connections with limited data volumes.

1.5 Components of the EcoPhi Basic Controller

1.5.1 Scope of delivery

In addition to the EcoPhi Basic Controller, the following components are supplied as standard:

- Key for opening the housing

- Mains cable with switch

- 2-, 3- and 4-pin connector for connection to the distribution board

- Heat-shrink tubing for simpler and tidier cabling

- Cable glands, consisting of gland, nut, rubber ring and plug

- Brackets and screws for attaching the Basic Controller to the wall

1.5.2 Internal components of the Basic Controller

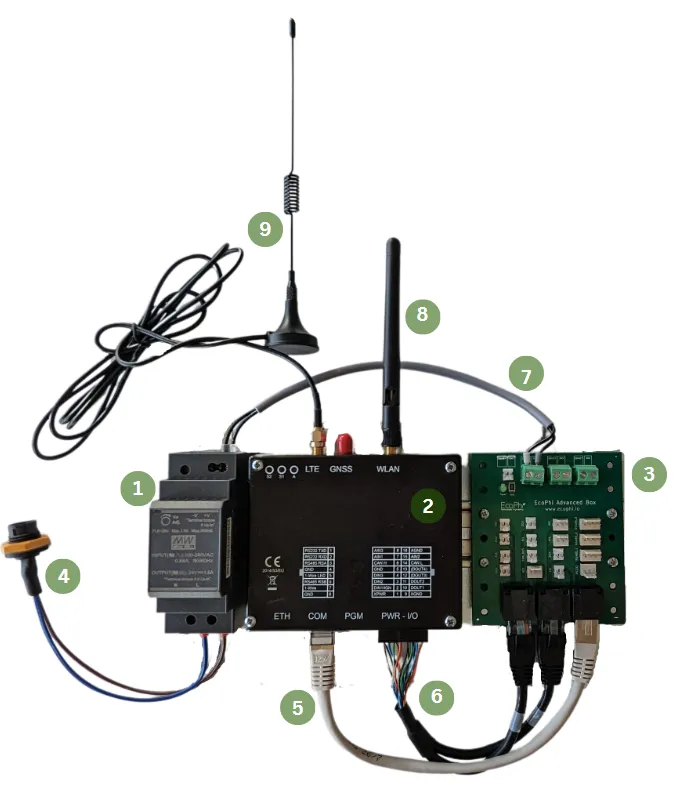

The EcoPhi Basic Controller consists of several key components housed in a robust casing.

1 Power supply: An integrated power supply unit ensures that all Basic Controller components are reliably supplied with power.

2 Data logger/main unit: This is the heart of the Basic Controller, which is responsible for processing and storing the data collected by the external device sensors. It also handles communication with the EcoPhi Cloud and other connected devices as well as the control logic.

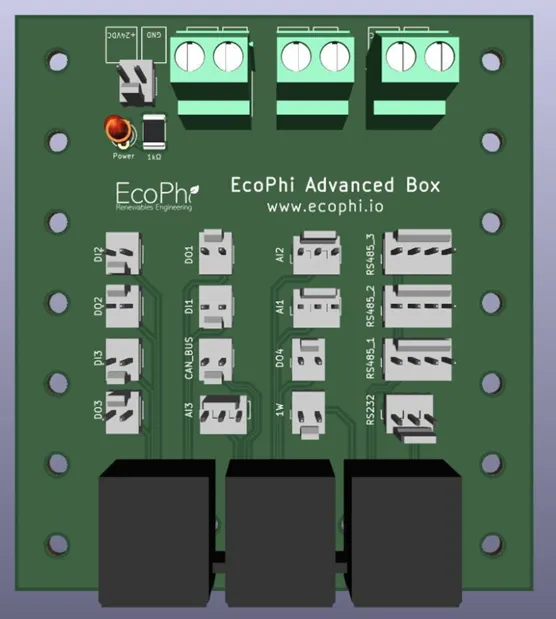

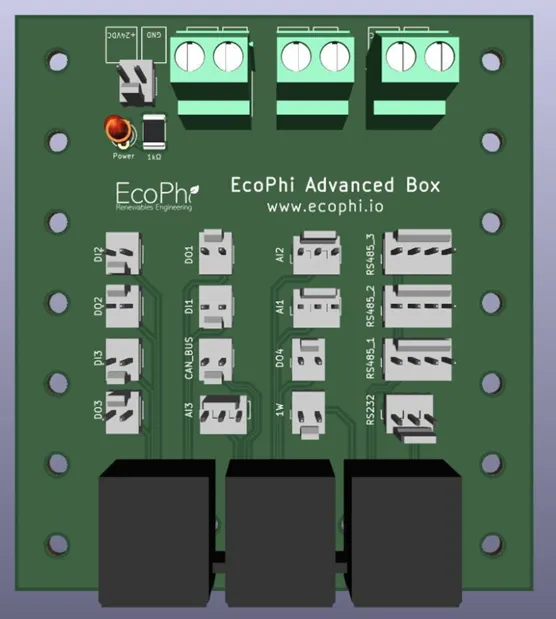

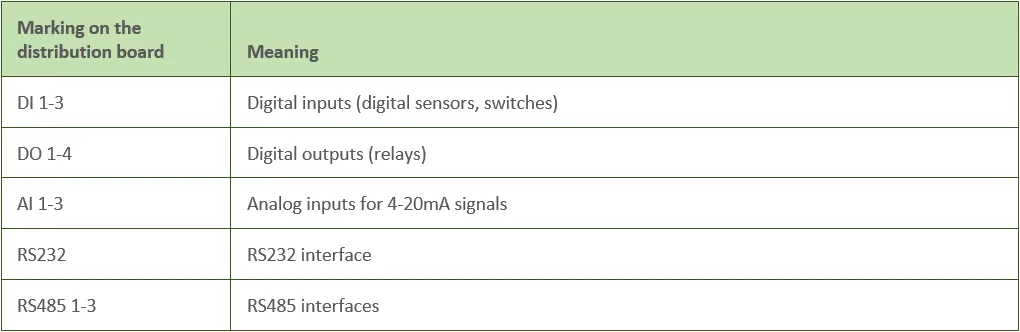

3 Distribution board: The distribution board was developed to simplify the connection of external devices, sensors and actuators. It offers a simple connection option, simplifies cabling and ensures a clear structure during installation.

4 Power supply cable: This cable is integrated into the housing of the Basic Controller. The Basic Controller can be supplied with a voltage of 230 V AC via the power supply cable included in the scope of delivery.

5, 6, 7 Internal cabling: These cables are used for data and signal transmission and power supply and must not be modified without consulting EcoPhi.

8 Wifi antenna: The Wifi antenna enables a connection to be established to a local Wifi network.

9 GSM antenna: The GSM antenna can normally remain inside the housing and still establish a sufficient connection. However, it can also be routed through the housing to the outside if the connection is too weak.

Housing with switch cabinet and door: All of the above components are housed in a robust control cabinet that offers protection against dust, moisture and mechanical influences. The door allows easy access to the internal components and can be locked for safety.

1.5.3 The data logger/main unit

The data logger/main unit is the heart of the Basic Controller.

1.5.4 LED lights for recognizing the device status

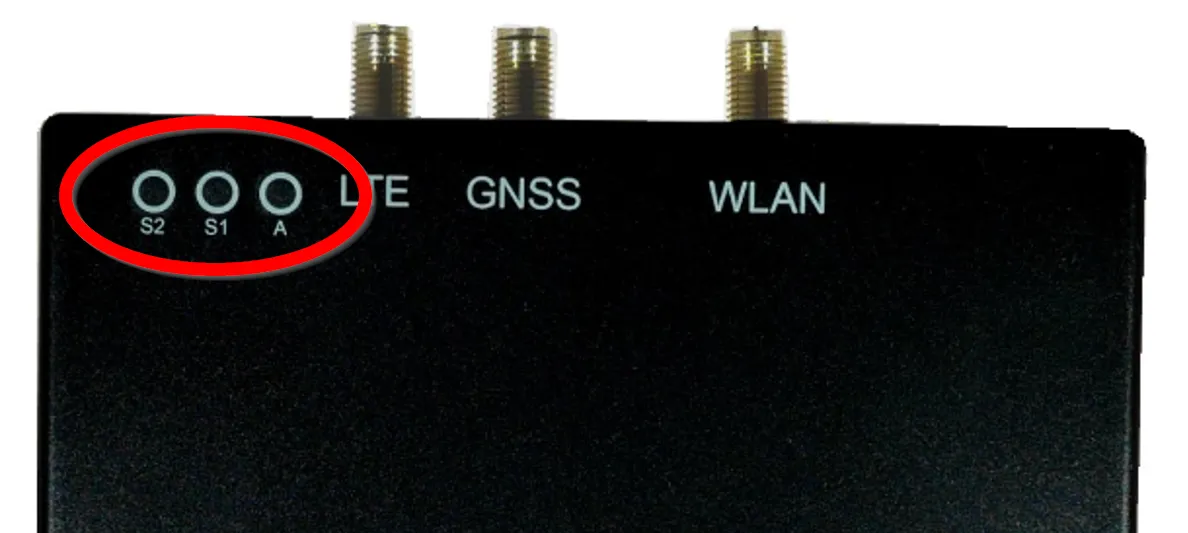

The EcoPhi Basic Controller provides visual feedback via various LEDs that indicate the status of the device and the connection. These displays are important for quickly identifying and rectifying problems.

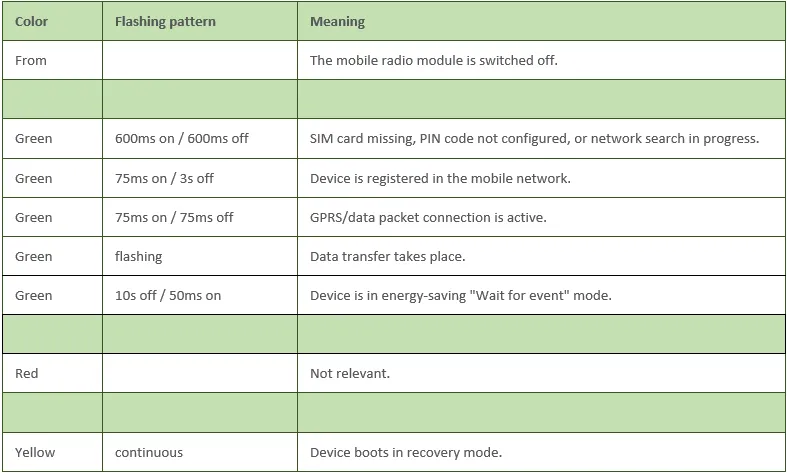

LED A: Internet connection

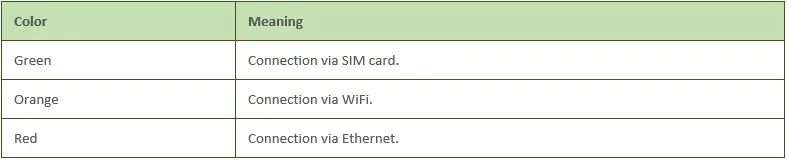

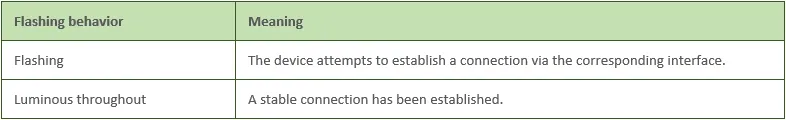

LED A indicates the status of the Internet connection. The colors and flashing patterns have the following meanings:

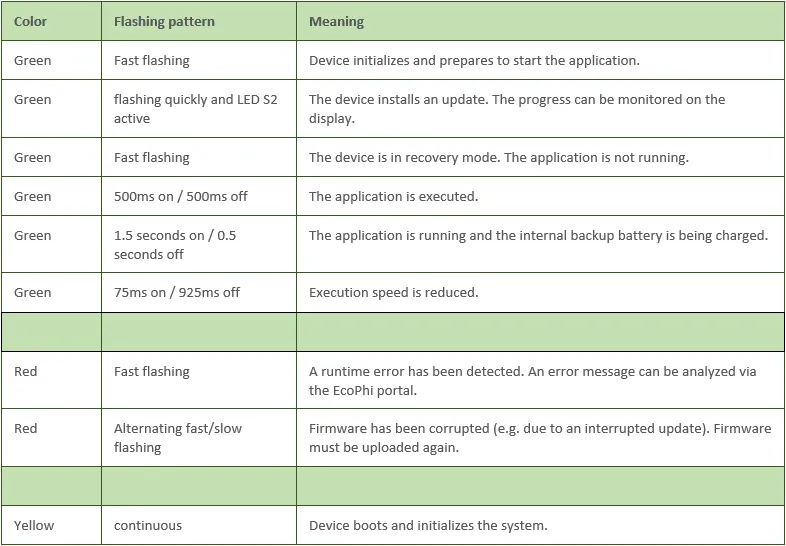

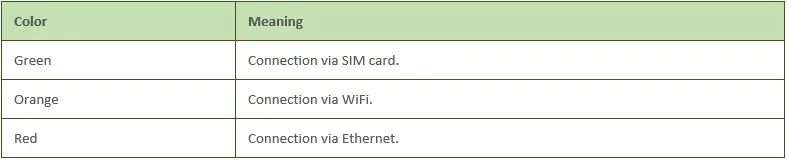

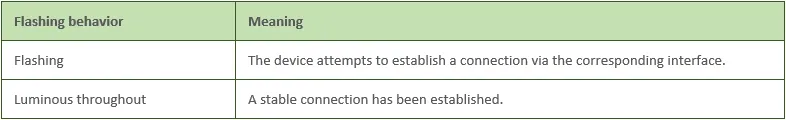

Color assignment of LED A:

Flashing and lighting behavior of LED A:

LED S1: General operating status

The system LED1 indicates the general status of the EcoPhi Basic Controller. The different flashing patterns and colors have the following meanings:

LED S2: Mobile radio activity and “Waiting for event”

The system LED2 provides information about the mobile phone connection and the operating status:

These LED indicators enable quick and easy diagnosis of the operating and connection statuses. In the event of a fault, they can provide important information for troubleshooting.

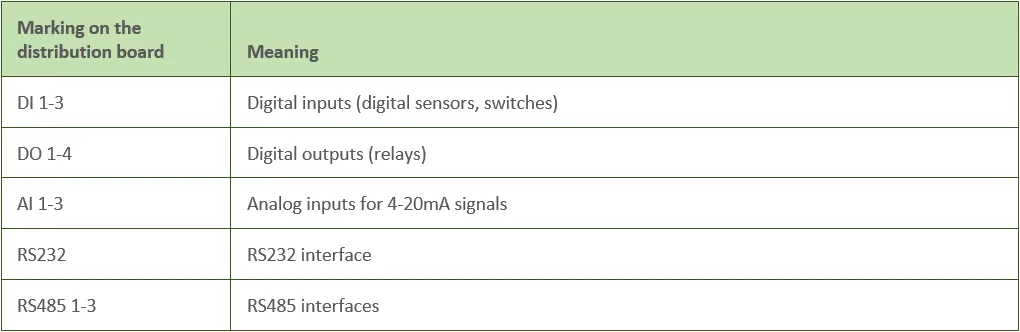

1.5.6 The distribution board

Connect the external devices, sensors or actuators to the distribution board using the 2, 3 or 4-pin connectors supplied. Use the marked and labeled pins on the distribution board. Observe the following pin assignment:

1.5.7 SD card

The EcoPhi Basic Controller has an SD card that performs several functions:

Intermediate storage of data: The SD card serves as a buffer when no internet connection is available. All data collected during offline time is stored on the SD card and automatically transferred to the EcoPhi Cloud later.

Configuration via SD card: The SD card can be used to save configuration files and transfer them to the Basic Controller. This is particularly useful if the device is installed in a remote location and the settings cannot be changed via the platform.

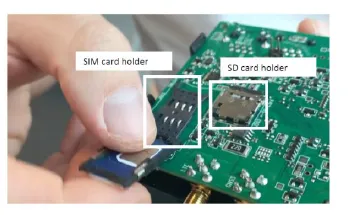

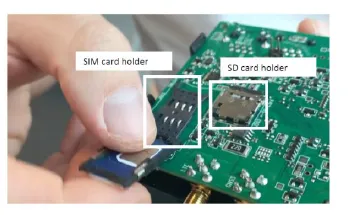

The EcoPhi Basic Controller is supplied with an SD card as standard. To take out and insert a card, open the EcoPhi Box, open the data logger inside and insert the SIM card:

- Take out the cover of the data logger by removing the screws to get access to the circuit board.

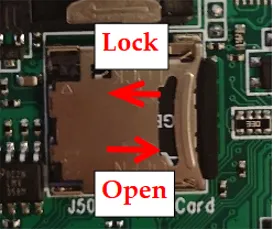

- Slide the metal clip on the SD card holder to unlock it.

- Take out the SD card.

- When you insert the SD card, slide back the metal clip to lock it.

- Put the cover back on the data logger and close the data logger with the screws.

1.6 Tools required for installation

The following tools and aids are required to install the EcoPhi Basic Controller:

- Electric screwdriver (slotted): For connecting the cables to the distribution board

- Phillips screwdriver: In case the data logger/ main unit needs to be opened

- Material for cable connection: For example, cable clamps, heat-shrink tubing or soldering materials.

- Hot air dryer or lighter: For shrinking heat-shrink tubing to insulate the connections.

- Cordless drill: For wall mounting of the Basic Controller or installation in a control cabinet.

2 Installation instructions

2.1 Quick Guide

This checklist will help you to carry out the installation of the EcoPhi Basic Controller in a structured manner. Please work through the points in order.

Preparation

- Make sure you have access to the EcoPhi Cloud platform.

- Select a suitable location that is easily accessible, offers reliable network coverage (mobile radio, WLAN or LAN) and enables the shortest possible sensor cables.

- Have the necessary tools ready, such as electric screwdriver, cordless drill, cable clamps and hot air gun.

- Check the scope of delivery of the Basic Controller, including power supply unit, connection cable, GSM and WiFi antenna as well as the supplied cables and cable glands.

Mechanical installation

- Attach the Basic Controller securely to the wall by mounting the housing with screws and wall plugs.

- Attach the cable glands and seal unused openings to protect the device from dust and moisture.

Electrical connections

- Connect the power supply and check the function using the LED activity.

- Set up the Internet connection via Ethernet, WiFi or SIM card.

- Wire sensors and actuators according to the requirements. Ensure that digital and analog inputs/outputs are assigned correctly and that the analog input types are set correctly (0-10V and 4-20mA).

- With RS485 cables, make sure that there are no external sources of interference in the vicinity to avoid signal interference.

- Connect RS485/RS232 devices and ensure that the A/B lines are not reversed.

Commissioning

- Connect the EcoPhi Basic Controller to the EcoPhi Cloud by registering the device in the platform and configuring the connected sensors in the “Site Settings”.

- Check the connection status using LED “A” and ensure that the network connection is stable.

Final check

- Check that all cables are firmly connected and correctly insulated.

- Make sure that there are no unused openings in the housing.

- Make sure that the Basic Controller is running stably and does not display any error messages or unusual LED displays.

2.2 Preparations

2.2.1 Access to the EcoPhi portal

User account: To be able to connect the EcoPhi Basic Controller, you need a registered user account and an associated entity at www.portal.ecophi.io. If no account exists, you can find more information on registration in the platform manual.

Create device as data source:

Log in to the platform.

Select an existing site or create a new one.

Add the Basic Controller as a data source by entering the device ID (e.g. m315******). This ID can be found on the side of the box.

Configure site settings:

Specific settings for the Basic Controller can be made in the Site Settings.

Components such as sensors or actuators that are connected to the Basic Controller can also be created here.

2.2.2 Preparations on the box

A few preparatory steps are necessary before starting the cabling:

Remove packaging material:

Remove all packaging material that is still inside the appliance to ensure correct operation.

Attach cable glands:

The housing is supplied with open holes to allow flexible cable routing. Screw the required cable glands firmly into the corresponding openings to ensure a secure and weatherproof seal.

Close any unused openings:

Seal all unused holes and feed-throughs with the plugs supplied. This protects the Basic Controller from moisture, dust and other environmental influences.

2.3 Connection with the EcoPhi Cloud

The EcoPhi Basic Controller communicates with the EcoPhi Cloud platform. This platform enables configuration of the device, management of the data and integration with other systems. Most settings are made directly on the platform and only in exceptional cases directly on the device. A stable internet connection must therefore be set up first.

2.3.1 Connection options

The EcoPhi Basic Controller offers three options for establishing an internet connection: Ethernet cable, SIM card and WiFi.

If multiple connection types are available, the device automatically selects the first working connection. This prioritization order (Connection Order) can be adjusted via the online portal if required.

2.3.1.1 Connection via SIM card

One of the simplest and most flexible methods of connecting The Basic Controller to the Internet is to use a SIM card. This method allows connection via the mobile network and is particularly suitable for locations without wired Internet access.

Inserting the SIM card:

Before the Basic Controller can establish a connection, a compatible SIM card must be inserted into the corresponding slot.

- Open the EcoPhi Box and take out the cover of the data logger by removing the screws to get access to the circuit board.

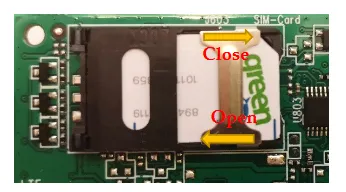

- Slide back the metal clip on the SIM card holder and fold it up.

- Insert a local SIM card with internet connection and without a PIN code.

- Close the SIM card holder and fasten the metal clip.

- Put the cover back on the data logger and close the data logger.

Configure the APN settings:

With some mobile phone providers, additional APN settings must be made in order to establish a connection. This can be done in two different ways:

By SMS:

Send a message with the following content to the SIM card number:

Message structure: apn:apn_name;apn_user;apn_password

(Example: apn:internet.t-mobile;user;password)

Via SD card:

Place a CSV file with the name command.csv with the APN settings in the main folder of the SD card. The file must have the following structure:

File content: apn:apn_name;apn_user;apn_password

(Example: apn:internet.t-mobile;user;password)

2.3.1.2 Connection via Wifi

The EcoPhi Basic Controller can also be connected to the internet via a WiFi network. This method is particularly suitable for locations where stable WiFi is available.

The WiFi settings can be configured in several ways:

Setup via the EcoPhi platform:

Log in to the platform and navigate to the Site Settings. Here you can enter the network (SSID) and password to configure the connection.

By SMS: If you have a mobile connection, you can also adjust the WiFi settings via SMS. To do this, send a message in the following format to the SIM card number:

Message content: wun:WiFi_name(SSID);WiFi_Password

(Example: wun:HomeNetwork;securepassword123)

2.3.1.3 Connection via Ethernet

The most stable method of connecting to the Internet is to use an Ethernet cable. This method is recommended if wired Internet access is available.

Connect the Basic Controller to a network router or switch by feeding an Ethernet cable through the marked large cable entry into the box and plugging it into the “ETH” connection of the device.

Check the LED “A” next to the connection:

- Flashing green: Connection active.

- Red: No connection.

Automatic connection: If the connection is not established immediately, the Basic Controller automatically attempts to establish a connection every 10 minutes. Alternatively, the device can be restarted manually to speed up the process.

2.3.2 Changing the Internet settings when no Internet is available

If the Basic Controller cannot connect to the Internet, there are several alternatives for changing the settings manually. Each method is tailored to different situations and requires specific steps:

By SMS

If a SIM card is installed in the device, the settings can be changed by sending an SMS. To do this, send a message with the desired changes to the phone number of the SIM card used.

Examples of SMS commands:

"status": Returns the current connection status.

"restart": Restarts the device.

"apn:apn_name;apn_user;apn_password": Sets the APN settings. (Example: apn:internet.t-mobile;user;password)

"wun:WiFi_name(SSID);WiFi_Password": Changes the WiFi settings. (Example: wun:HomeNetwork;securepassword123)

Use of a hotspot

If no permanent Wi-Fi is available, a smartphone can be used as a temporary hotspot. This is particularly useful for tests or short-term connections during commissioning.

Use the following settings:

Network name: aveefunky_2,4

Password: funky2015avee2019

Per EcoPhi Portal

To temporarily connect to the EcoPhi portal, you can create a hotspot. If the device can be successfully connected to the EcoPhi platform in the short term, Internet settings can be adjusted via the portal:

Log in to https://portal.ecophi.io.

Navigate to the “Site Settings”.

Adjust the required settings for the device.

Via SD card

Another way to change the settings is to use an SD card.

Create a CSV file with the file name command.csv and the required settings. Message structure:

apn:internet.t-mobile;user;password: Sets the APN settings.

wun:HomeNetwork;securepassword123: Sets the WiFi settings.

Save the file in the root directory of the SD card.

Insert the SD card into the Basic Controller and restart the device. The Basic Controller automatically adopts the new settings.

2.3.3 Meaning of the LED lights on the controller/main unit

The LED “A” on the Basic Controller is a key tool for monitoring the status of the Internet connection. It not only shows the type of connection, but also its status. This visual display helps to identify the status of the Internet connection and to take appropriate measures to rectify faults if necessary.

The different colors and states have the following meanings:

Color assignment of LED “A”:

Flashing and lighting behavior of LED “A”:

Examples:

LED “A” Flashing green: The Basic Controller is trying to establish a connection via the SIM card.

LED “A” solid orange: The connection via WiFi has been successfully established.

LED “A” Flashing red: The device is trying to establish a connection via Ethernet.

2.3.4 Antennas

The EcoPhi Basic Controller is equipped with a GSM antenna (for the mobile phone connection) and a WiFi antenna as standard. These antennas enable reliable data communication and are crucial for the connection to the EcoPhi Cloud.

Standard operation of the antennas: The antennas are installed in the device and work reliably inside the housing in most cases. However, if the connection is impaired by metallic shielding (e.g. by a metal housing or walls), it may be necessary to route the antennas to the outside.

Signal display: The reception of the antennas can be viewed directly via the display. The signal strength and quality of the connection can be checked here. This helps to identify problems and enables targeted optimization of the antenna alignment.

Improve signal reception: If the signal quality is insufficient or connection dropouts occur, it is advisable to move the antennas to the outside. The Basic Controller stores unsent data for up to several months and transmits it automatically as soon as the connection is re-established. This means that no important information is lost.

2.4 Cabling

This chapter describes how to wire the EcoPhi Basic Controller. As the connections can vary greatly depending on the application, you will find general guidelines, specific instructions and technical details on the connections here.

2.4.1 Circuit diagram of the distribution board

Various devices and sensors can be connected to the distribution board of the EcoPhi Basic Controller. Please refer to the following diagram for the exact pin assignment and connections. This circuit diagram shows which connections are intended for which device types.

Connect the external devices, sensors or actuators to the distribution board using the 2, 3 or 4-pin connectors supplied. Use the marked and labeled pins on the distribution board. Observe the following pin assignment:

The wiring diagram helps you to identify the correct connections for your specific applications.

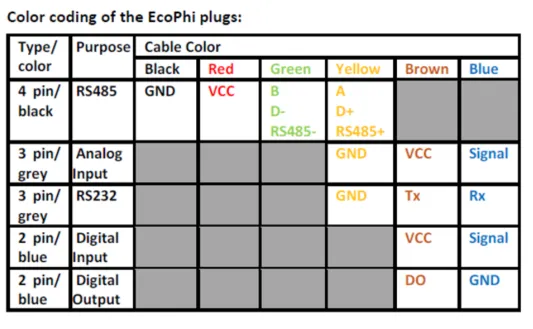

2.4.2 Color coding of the EcoPhi connection cable

Use the supplied connection cables with the 2.3 and 4-pin connectors to connect external devices or sensors to the distribution board of the Basic Controller. Take the following color codes into account:

2.4.3 Connecting external devices and sensors

Use the 2, 3 or 4 PIN connectors supplied for connection. Connect these to the sensor or external device according to the sensor or device specification, guide the cable end with the PIN connector through one of the openings in the housing and plug the PIN connector into the corresponding slot on the distribution board. The Basic Controller supports a large number of external devices, sensors and actuators. Depending on the type, these are wired as follows:

2.4.3.1 Digital inputs (DI1-DI3)

The digital inputs work with two pins (VCC and signal) and are designed as wet contact inputs (24V). They can be used for simple switching states (“On/Off”) as well as for pulse counting.

Pulse counting: The maximum counting frequency is 10 kHz.

2.4.3.2 Digital outputs (DO1-DO4)

The digital outputs consist of two pins (signal and GND) and work with wet contact signals (24V).

Maximum load: Up to 1A current and 20mH inductance.

Application: For controlling devices such as relays or contactors.

2.4.3.3 Analog inputs (AI1-AI3)

Analog inputs work with three pins (VCC, GND, signal) and support two modes:

- 4-20 mA mode: For current output sensors (Standard setting for the Basic Controller)

- 0-10 V mode: For voltage output sensors

Changing the modes for analog inputs

It is possible to switch to 0-10 V mode by removing the jumpers inside of the data logger.

To change an analog input to 0-10V:

- Open the EcoPhi Box and take out the cover of the data logger by removing the screws to get access to the circuit board. The jumper positions are labeled Ain 1 - Ain 3 which correspond to the sockets AI1 - AI3.

- Remove the respective jumper (Ain 1-3).

- Put the cover back on the data logger and close the data logger.

2.4.3.4 RS485/Modbus RTU (RS485 1-3)

The RS485 connections consist of four pins (VCC, GND, RS485A, RS485B) and enable the connection of RS485-capable devices. All three connections are connected in parallel and connected to a port on the data logger/main unit.

2.4.3.5 RS232 (RS232)

This connection is used to connect RS232-capable devices such as solar inverters. It consists of the GND, TX and RX pins.

2.4.3.6 Ethernet/Modbus TCP (ETH port on the data logger)

Use a standard CAT cable for the Ethernet connection (ETH) to connect wired networks or Modbus TCP devices.

2.4.4 Restart

The restart button of the Basic Controller is located on the top of the data logger between “GNSS” and “WLAN”. To press the button, please use a small and firm tool such as a paper clip or pin. Press this into the hole until you feel a resistance.

It should be used in the following situations:

New SIM card: After inserting a new SIM card, the device must be restarted so that the card is recognized and configured.

Malfunction of the device: If the device shows unusual behavior or cannot connect to the platform, a restart may help to resolve the problem.

The restart ensures that all processes on the device are reset and restarted without deleting saved data or settings.

2.5 Wall mounting

The EcoPhi Basic Controller is installed by attaching the supplied brackets to the housing.

Select the installation location: Choose a suitable location that is easily accessible and offers good network coverage.

Fastening the brackets: Attach the brackets to the housing using the screws supplied as shown.

Mounting on the wall Attach the EcoPhi Basic Controller securely to the wall using the four brackets and suitable screws and plugs. Make sure that the housing hangs horizontally to allow easy cabling.

Cable management: Route the cables neatly through the cable grommets provided and secure them with cable ties if necessary to avoid clutter and ensure a secure installation.

3 Controls

The Basic Controller allows simple controls such as switing relays. The control functions of the EcoPhi Basic Controller are specially tailored to the needs of individual applications and are configured in close coordination with EcoPhi.

3.1 Individual controls

The EcoPhi Basic Controller controls are set up individually and are only available on request. This ensures that the controller is precisely matched to the requirements of the respective system. If you are not sure whether a individual controls are available for your application or is part of your system, please contact your dealer or EcoPhi sales agent directly.

Settings of the control parameters:

The control parameters can be configured via the EcoPhi Cloud under the “Action Conditions” section. This functionality enables

- Assignment of control logic: Specify which conditions should trigger certain control actions.

- Data provision: Provide the controller with the necessary data points (e.g. sensor data or operating states).

- Optimize system performance: Monitor and adjust control parameters as needed to ensure optimal performance.

4 Error messages

This chapter describes how you can proceed in the event of errors or problems with the EcoPhi Basic Controller in order to identify and, if necessary, rectify the causes.

LEDs flash red quickly

If all the Basic Controller LEDs flash red quickly, this indicates a hard fault in the software. This is a critical error that puts the device out of operation. In such cases, the following steps should be taken:

Restart the device: Press the Restart button to reset the device. In many cases, this will temporarily rectify the error so that a new connection to the platform can be established.

Contact support: If the error persists, contact EcoPhi Support. Make a note of the exact time of the error and all observed symptoms to enable a quick diagnosis.

Touch screen no longer responds and LEDs S1 and S2 flash monotonously or are off

This behavior indicates a serious internal fault, which is usually caused by GND faults in connected devices. Poor earthing can result in voltage differences between the EcoPhi Basic Controller and the connected devices (e.g. via RS485 or Ethernet) having to be reduced. This can cause internal damage to the Basic Controller. In such cases, the following steps should be taken:

Contact EcoPhi Support: Disconnect the device from the power supply and the connected devices and report the problem to EcoPhi Support. Describe the connected devices and the cabling in order to narrow down the cause of the problem.

Check earthing: Ensure that all connected devices are properly earthed. Poor earthing can lead to voltage differences that are equalized via the communication lines (e.g. RS485 or Ethernet) and can therefore cause damage.

Sensor or externally connected device is not responsive

If a connected sensor or external device does not respond or does not provide any data, proceed as follows:

-

check cable connections: Check that all cables are correctly and firmly connected to the corresponding pins. Also check whether there is any visible damage to the cables, such as breaks or corrosion.

-

check the status on the display: For analog and digital sensors: The status of these sensors is shown live on the Basic Controller display. A signal displayed as “On” or “Off” (for digital sensors) or as a bar (for analog sensors) indicates that the device is correctly wired. If no signal is visible, there may be a wiring error or a defective sensor.

-

check serial connections: RS485 or RS232 connections cannot be checked directly via the display. These connections are diagnosed via the cloud or a debugger on site.

-

RS485 device does not respond: If an RS485 device does not respond to commands, carry out the following steps:

Check Modbus ID: Ensure that the Modbus ID of the connected device is configured correctly.

Check the wiring: Check that cables A and B are connected correctly and are not reversed. Incorrect polarity means that no data can be transmitted.

Termination: Check whether a termination resistor (typically 120 Ohm) has been inserted at the end of the RS485 line. Signal interference can occur without this resistor.

Signal interference: Ensure that the RS485 cable is not routed near high-voltage lines or other sources of electromagnetic interference.

Debugging: Use a debugging tool or a protocol analyzer to check the data traffic on the RS485 line. This can help to identify communication problems.

- settings in the platform: Check in the platform whether the settings for the corresponding sensor are correct (e.g. readout frequency, Modbus port or Modbus TCP port).

If the platform shows the connection to the sensor but the data does not appear correctly, the problem may be with the sensor itself.

5 Support and further information

If you encounter any problems with the EcoPhi Basic Controller during installation, configuration or operation, our support team will be happy to help.

Please create a ticket via our online ticket system: https://ecophi.io/support-request/

Our team will get back to you promptly with a solution or further instructions.

EcoPhi Renewables Engineering GmbH

Alter Schlachthof 33

76131 Karlsruhe

www.ecophi.io